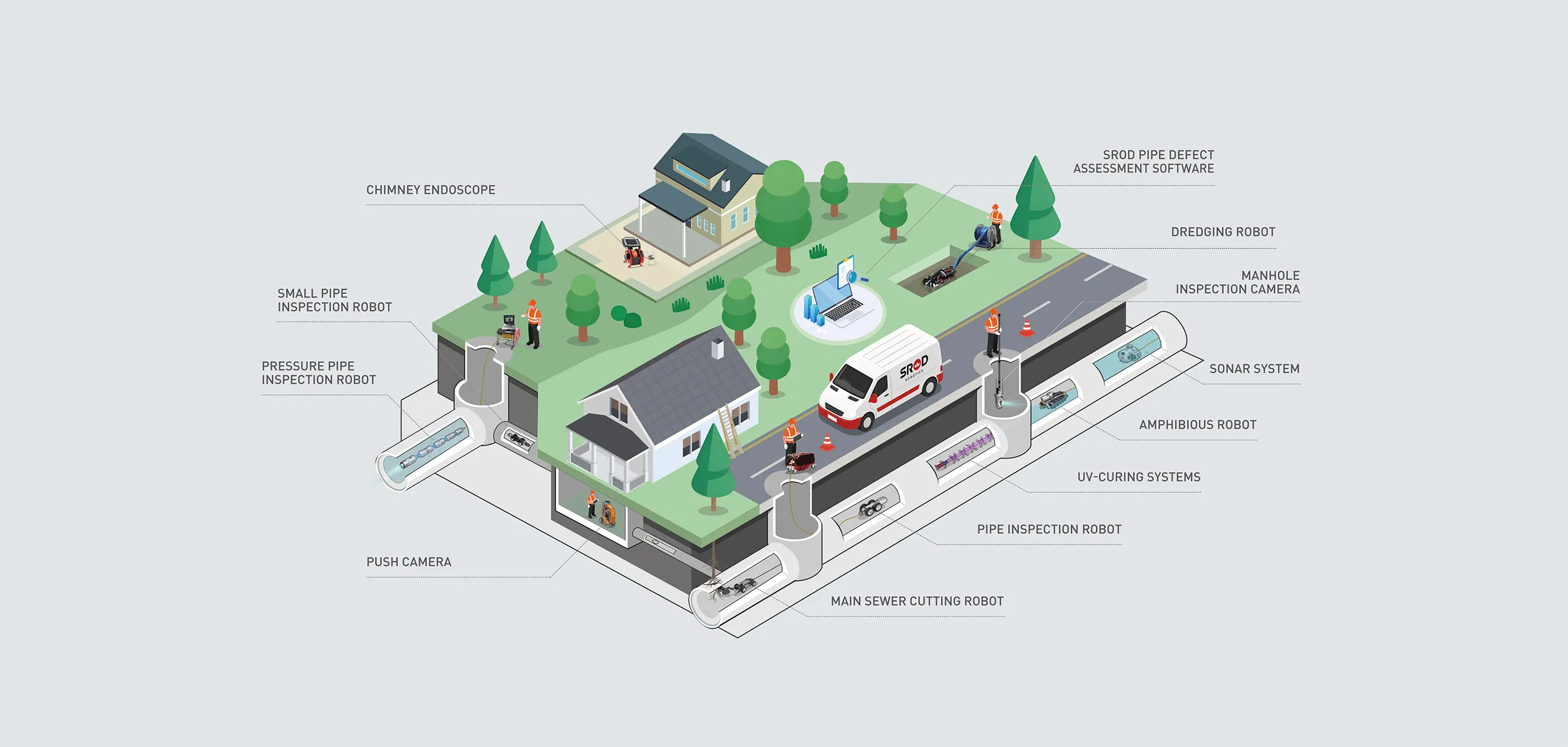

APPLICATION SCENARIO

WHY CHOOSE US

Shenzhen SROD Industrial Group Co., Ltd. (“SROD ROBOTICS”)is a pioneer of embodied intelligent special-purpose robots focusing on confined space,concentrating on confined spaces and extreme operating condition,the products are used in urban underground pipe networks, intelligent inspections in industrial and mining industries, emergency rescue and other field.

40+

Sales countries and regions

7000+

Service Customers

400+

Intellectual property rights

30+

Industry standards

Global SROD

Let special robots become the guardians of human safety

SROD's products and services span international, footprints span over 40 countries and regions worldwide, and are trusted by more than 3500 Customers, build a strong market network.